Historical Evolution and Future Trends in Quality Management Systems

As we see it today, the history of quality management software was used earlier in different ways. So as

As we see it today, the history of quality management software was used earlier in different ways. So as everything in life has changed over time, let’s go a little backwards in time and see how it was earlier in order to understand where we are now and to be able to think about what it could be like in the future.

The importance of quality is not a new issue. It has been since time immemorial. The quality has been defined from several perspectives. There are 4 different definitions of quality depending on which perspective you are referring to and while we refer to the dimensions of the quality each dimension refers to a particular context or perspective.

Quality has been a serious concern in all mankind which has developed. But before we refer to the various kinds of tools & techniques we use under quality design and control, we should be aware of how the concept of quality used to be perceived in ancient times.

Historical Evolution of Quality Management Software

- Quality in the Mediaeval Guilds of Europe- In Europe, craftsmen began organizing unions called guilds in the late 13th century to develop strict roles for products and services. Quality and inspection committee enforce their role by marking flawless goods with special symbols. Craftsmen themselves often placed a second mark on the goods they produced. The same practice was approached by manufacturing quality that dominated until the Industrial Revolution in the early 19th century.

- Quality in the Industrial Revolution- Quality in the Industrial Revolution had three sub-items: craft shipment, the factory system and the taylor system. The craft shipments model was used until the early 19th century. Great Britain started emphasizing product inspection in the 7050s and grew into the Industrial Revolution in the early 1800s. Quality in the Industrial Revolution has three parts. Those three parts are-

- Craftsmanship- In the early 19th century, the United States also followed the craftsmanship model and they maintained a form of quality control by inspecting goods before sale.

- The factory System- Quality in the factory was ensured through the skill of labourers supplementary through audit and inspection. Effective products were either reworked or scrapped.

- The Taylor System- Late in the 19th century, the US broke the European tradition and adopted a new management system approach developed by Mr Frederick W. Taylor. His goal was to increase productivity without increasing the number of skilled craftsmen and they achieved that by assigning factory planning.

- Quality in World War II- During this period, the Quality Management system became a critical component of the war effort and an important safety issue as well which required huge inspection personnel to inspect the military equipment. Industrial consultants used to develop a military standard that is MIL-STD-105. Armed forces supported suppliers in improving quality by sponsoring training courses. They also helped suppliers improve quality by using Walter Shewhart’s techniques called statistical quality control (SQC).

- Quality in the Early 20th Century- Mr. Shewhart began to focus on controlling processes in the mid-1920s. Making quality relevant not only for the finished product but for the process that created it and data analysis by using statistical techniques. He laid the foundation for the control chart now it’s called a quality tool.

- The History of Total Quality in America- It also has 2 sub-items: Deming, Juran and Japan and the second one is The America Total Quality Management Response. Deming, Juran and Japan- Mr Edward Deming (Quality Expert) brought more programs for statistical quality control, and Mr Juran, the other Quality Expert, focused on improving all organizational processes through the people who use them. As a result, Japan was able to produce higher-quality exports at lower prices.

- The American total quality management response- The chief executive officer of the U.S. corporation stepped forward to provide personal leadership in the quality movement. The US response emphasizes not only statistics but approaches that embrace the entire organization which is known as total quality management (TQM) and several other quality initiatives are followed. ISO 9000 series of quality management standards were published in 1987.

- Beyond Total Quality Management- New quality systems have been pulled beyond the foundation tied by Deming, Juran and the early Japanese practitioners of quality. Most recently quality management 2015 the ISO 9001 software standard. It is revised to increase emphasis on risk management as well. Quality has moved beyond the manufacturing sector into such areas as service, healthcare, education and government. As a part of business, the quality management system has to be implemented fully for the better future of the organization.

Quality is the Future of Quality Management

In the era of Industry 4.0, Quality has become increasingly popular in marketing and business communication. It is not just a catchy buzzword trend that will disappear soon. Still, it’s a revolution that will reshape what quality and service can do and it’s here to stay.

Smart quality empowers life sciences companies to become quality-oriented, not just an unavoidable expensive cost of doing business but a value catalyst. It has the most effective pillars which are as follows-

Now most organizations do have a QMS in some form or the other as a SAP module or something else but the integration is different because you get various elements whether it is a service like PLM, ERP, FSM, CRM, EH&S, and SCM.

These are all different from each other and have their speciality. Only 8% of organisations have integrated EQMS and only 21% have adopted a core EQMS.

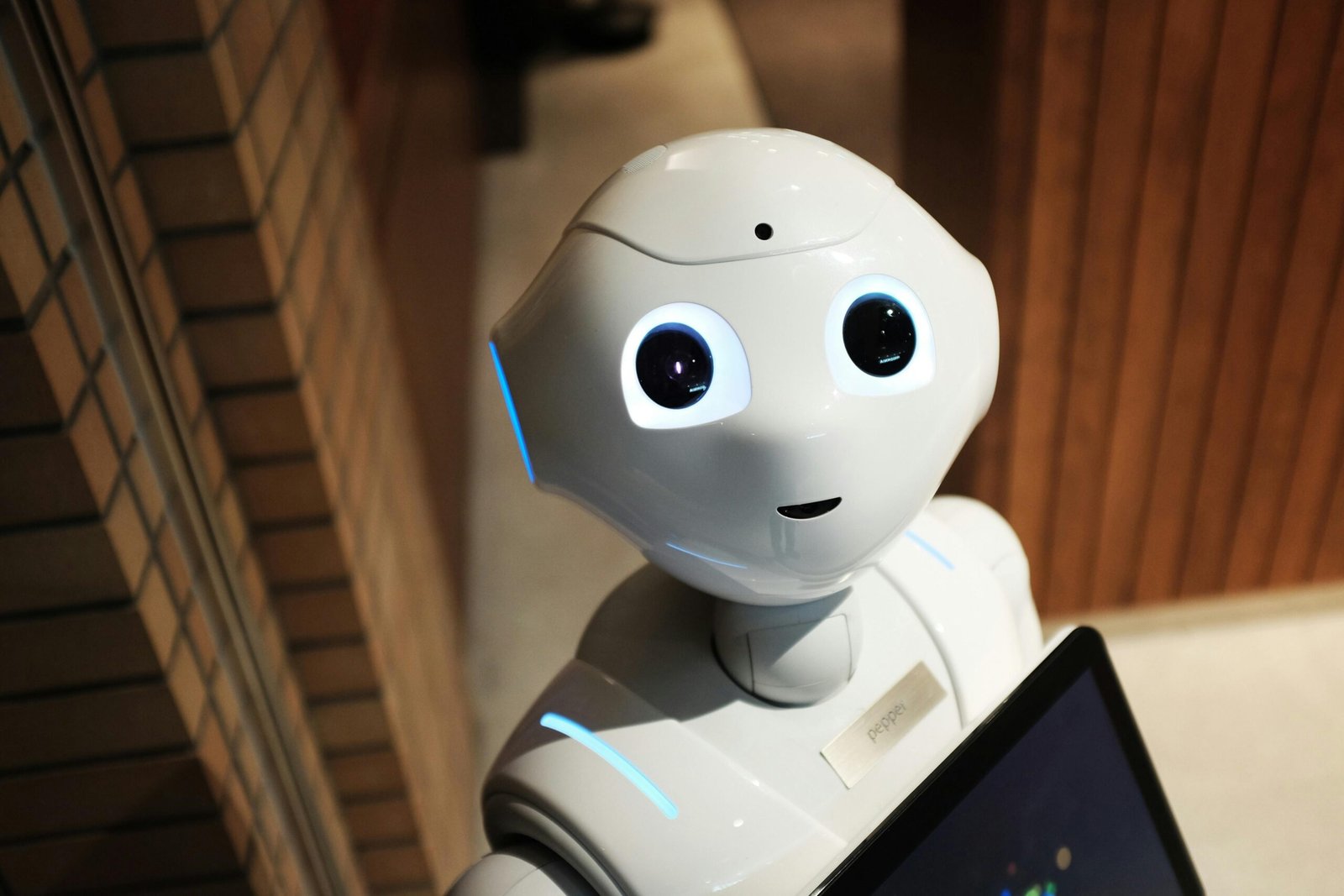

The future of our products as we are going to get more and more automated and machine-to-machine communication. Human control is going to become less in the sense that we are not going to control transactional activity.

The quality of our products is going to be in the future determined by the quality of the application that we are using digitized processes and systems. That doesn’t mean we can leave things on AI. We need professionals who are experts in managing systems software. The future is going to be changed with the positive growth of systems.

Conclusion

With such an illustrated format, we understand the history of quality management performed by different specialists. The historical revolution QMS software describes the pattern of change and conflicts that happened between finding out the right strategy.

The future of Quality management will not end soon. Every organization wants to grow their firm systematically and it is not possible without quality. Artificial intelligence, machine learning, integrated QMS, advanced data, and analytics are the future trends of quality management systems that shape organizations.